Advancements in technology have allowed crop irrigation pipelines to run with minimal problems for years at a time. New products and techniques such as digital control panels, sprinkler packages, and protective coatings like galvanizing have extended these machine’s lives considerably, and have secured irrigation pipelines as a lasting investment.

Galvanizing is one of the more significant techniques to extend pipeline life. The galvanizing process applies a protective coating to metals to prevent rusting. The most common method is hot-dip galvanizing, in which parts are submerged in a bath of molten zinc.

When a product is coated with zinc, it prevents corrosive substances from reaching the underlying steel or iron. The zinc also serves as a self-healing defensive layer, so that even if the coating is scratched, the exposed steel will still be protected by the remaining zinc. The coating also protects its base metal by corroding before the metal. However, even with advancements in galvanizing and other technologies, corrosion issues can cause a pipeline to not meet customer expectations.

More details on the galvanizing process can be found in our downloadable guidebook.

Where the Issue Started

Details on pipeline problems started to be documented in the Middle East during the mid-1980s. Farmers in Saudi Arabia and Libya kept encountering issues with their irrigation machinery, with problems ranging from significant leaks, to structural failures and cracks.

In a farming region south of the central city of Riyadh, Saudi Arabia, farmers were encountering these issues with their pipelines. Little did the farming community know, hydrogeologists had discovered that aquifers in the area contained above agerage pH levels, along with high levels of chlorides and sulfates.

The data these engineers collected established water quality in aquifers as the most significant effector of pipeline metals. They also concluded that crop protection products, chemigation, sulfur products, fertigation programs, and fertilizers degraded the water quality, which had caused problems in the past.

After further analysis, the engineers focused their efforts on the specific effects of chlorides, sulfates, and dissolved gases like oxygen and carbon dioxide. They attempted to develop prospective solutions to combat water quality, which included improved drains and epoxy coatings over galvanizing. While some of these fixes were promising, they eventually began to wear down and did not resolve the problem.

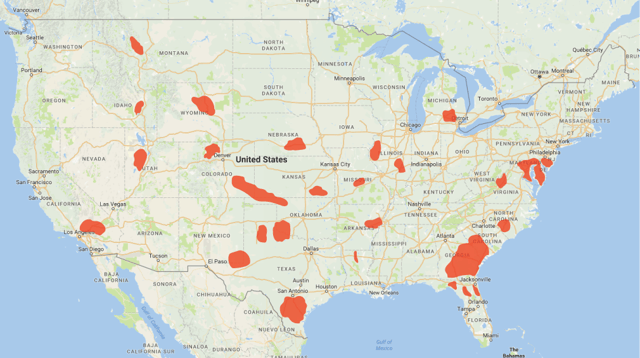

During this same time in North America, research teams discovered identical water quality issues in aquifers located in Texas. After reviewing their findings, they found more and more areas across the country had the same problems. Sulfates, and chlorides were presented in a variety of areas throughout the United States. Throughout the 1990’s North America posed more issues to engineers. Soft water found in Delaware, New Jersey, and Georgia lacked essential minerals such as calcium and magnesium. Without these elements in the water, the galvanizing couldn’t form a naturally occurring protective film.

Sometimes two fields next to each other had completely different water quality due to two different aquifers having different chemical concentrations. It all depended on the chemical makeup of the water in the aquifer, which could change throughout the year with seasonality.

See the aquifer section in our guidebook for more details.